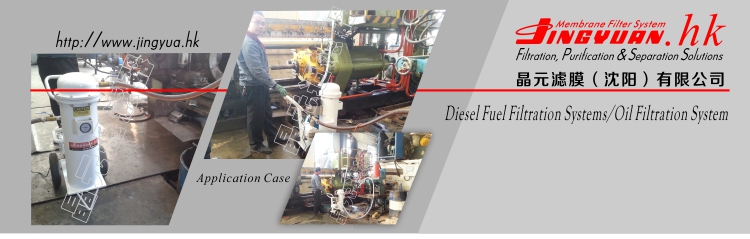

Hydraulic Oil Purifiction and Filtration-- Aluminum Molding and Processing Equipment Applicaton Case

Customer: Liaoning Aluminum Industry Co., Ltd.

Problem:

After being used a period of time, the hydraulic oil was polluted by colloid. As a result, the cleanliness of oil decline.

Solution:

Purchase one set of JYH130 Engine Oil/ Hydraulic Oil/ Gear Oil Refined Filter to remove impurity particles and colloid contained in oil.

Technical Index:

Model Type: JY-H130

Flow Rate: 30~40 L/min (Depends on the viscosity and temperature of oil)

Filtration Precision: 2~20μm (According to system requirements)

Filtration Material: Jingyuan Polymer Membrane Material(Various types,and can be used repeatedly after washed )

Working Pressure: 0.2~0.35 Mpa

Working Temperature:-10~70℃

Suitable Oil: Hydraulic oil, engine oil, gear oil ( Petroleum or mineral base oil)

Voltage: 380V (Continuously work for long time)

Measurement: 450*700*890mm

Weight:45Kg

Function:

Pump the oil from systematic tank. The oil passes through magnetic filtration and crude filtration firstly, then passes through Jingyuan polymer membrane filter elements. The polluted oil goes into the elements from surface and the clear oil flow out from inside, and the impurity and water are intercepted outside.

Maintenance:

If the pressure reaches 0.5~0.6 Mpa indicates that the filter elements has been blocked (please pay more attention to the case). Regular maintenance can improve the service life of filter elements significantly.

Filter Elements:

Jingyuan membrane filter elements assembly, the average service life of them is 2~3 years or longer (Depend on maintenance and oil quality)

Flow Path:

Oil passes through magnetic filtration firstly to intercept iron particles, then passes through the first tank (input mouth) to remove major particles, passes through the second tank (output mouth) to remove micro particles and water.

Filtration Necessity:

Solid particle pollution leads to the failure of hydraulic system and lubricating system, so it is necessary to filter the industrial oil before pour it into system. As the new oil (even just abstracted from tank) has been polluted seriously, it isn’t suitable for direct use. There are various reasons cause new oil pollution, such as contamination and water, they are likely mixed into the new oil during mixing and storage process.

Upgrade Model: JY-H330 Three Stage Hydraulic System Demulsification System

Filter the new oil, and pump the oil from oil storage tank to systematic oil tank. Purify the oil being used, and improve the performance of oil filtration. The filter can be used in the refined purification for hydraulic oil, gear oil and lubricating oil, break the emulsified structure, remove trace water contained in oil(ppm).

For more information about JY-H330, please click the link below:

http://www.jingyuan.hk/en/productview-id-36.html